¿Cuáles son los métodos de procesamiento de la correa de distribución perforada?

Perforated timing belt is a special belt widely used in mechanical transmission systems to transmit

power and realize various motion transmissions. It has the characteristics of compact structure, stable

transmission and reliable operation, and is widely used in industrial fields. In order to ensure the

normal operation of the timing belt, the correct processing method is very important, and it is the key

to ensure the normal operation of the timing belt. Improves the performance and life of the timing belt,

ensuring it transmits power efficiently.

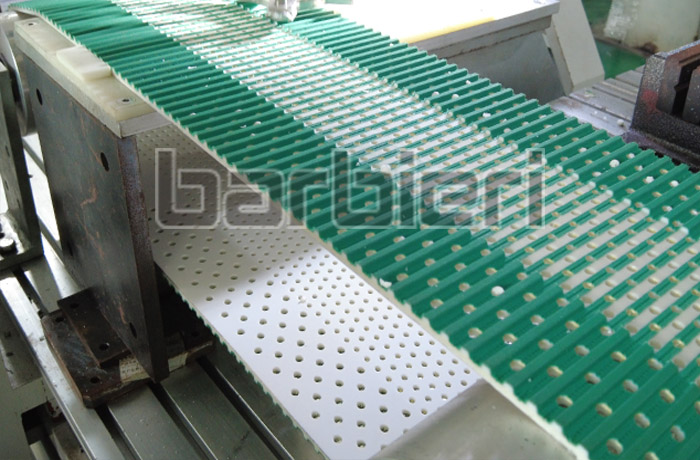

Barbieri Timing Belt CNC Programming Machinin Drilling High-precision processing, accurate position

ing of the width and depth of the timing belt hole, to ensure uniform drilling, accurate size and position.

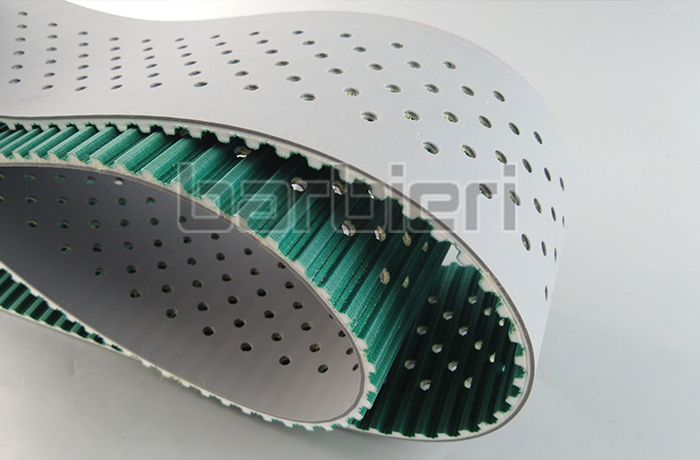

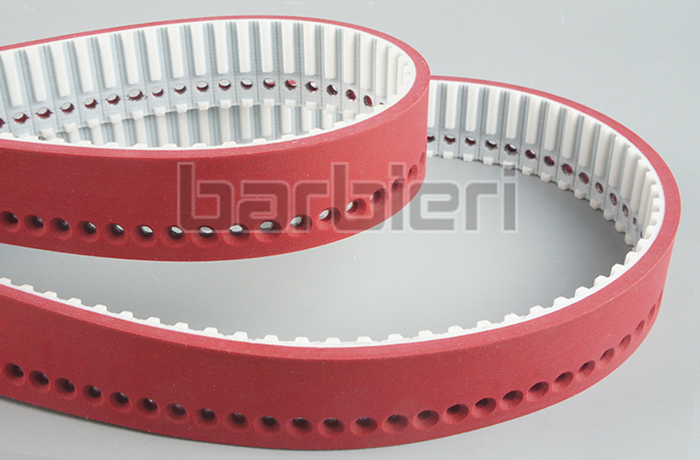

There are two common punching methods for timing belts: through holes and counterbores. Through

holes: mainly circular through holes; completely penetrate the timing belt; counterbores are round, oval,

square, diamond, and tapered .

The purpose of punching holes in the timing belt is for suction, so that the product can be close to the

surface of the belt when it is conveyed on the timing belt, so that the product can be conveyed in a nor-

mal and orderly manner; the drainage function can be used in the transportation of cleaning products

to make the conveyance The water on the belt flows away; fixed products such as attachment nuts and

fixtures can be installed to achieve accurate positioning, which will not affect the operation of the timing

belt and can meet the needs of different mechanical devices. Barberry can customize special shaped

holes according to customer requirements.

Add silicone timing belt tooth surface, add green and drill through holes

Kevlar rope core timing belt tooth surface milling slot plus through hole

Add red plastic timing belt tooth surface milling groove and counterbore

Rubber Timing Belt Tooth Surface Milling Groove and Counterbore

- Correa dentada de poliuretano

- Correa dentada anular

- Correas de distribución abiertas

- Correas dentadas de la serie AT

- Correas dentadas de la serie T

- Correas dentadas de la serie STD

- Correas dentadas de la serie HTD

- Correas dentadas de la serie RPP

- Correas dentadas de la serie TT5

- Correa dentada serie imperial

- Serie de correas planas de poliuretano compatibles

- Correa dentada de doble cara

- Correas dentadas de la serie ATN

- Correa de distribución con respaldo

- Correa dentada con tela

- Punzonado de la correa de distribución

- Correa dentada de seguimiento automático de poliuretano

- Correa Poliuretano Con Perfil

- Correa dentada de procesamiento especial