¿Cuáles son las diferencias entre las correas de distribución de poliuretano y las correas de distribución de caucho en términos de materiales, rendimiento y escenarios de aplicación?

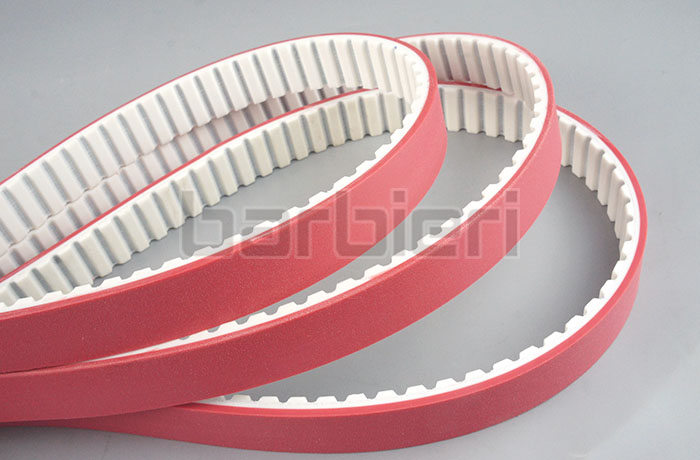

Polyurethane timing belts and rubber timing belts are widely used industrial belts. They play an important role in various mechanical equipment with their respective advantages and have won high recognition from both inside and outside the industry. However, there are significant differences between the two in terms of materials, performance and application scenarios. By deeply understanding the materials, performance and application advantages of the two, we can make more informed decisions and provide reliable transmission support for the efficient and stable operation of the equipment.

The following is a comparison of some of the main polyurethane timing belts and rubber timing belts compiled by the editor:

1. Material properties

Features | Polyurethane timing belt | Rubber timing belt |

Belt material | Polyurethane (PU) | Chloroprene rubber (CR)/ Nitrile rubber (NBR), etc. |

Tensile layer | Galvanized steel wire core/Stainless steel wire core/Aramid fiber core (Kevlar core) | Glass fiber core/ Aramid fiber core (Kevlar core), etc. |

Hardness | High (good wear resistance) | Low (better elasticity) |

Processing technology | One-piece injection molding, high tooth shape accuracy | Vulcanization molding, low tooth shape accuracy |

2. Performance comparison

Performance | Polyurethane timing belt | Rubber timing belt |

Abrasion resistance | Excellent (suitable for high frequency and high load scenarios) | General (easy to wear after long-term use) |

Oil resistance | Excellent (resistant to oil and grease corrosion) | General (requires specific rubber formula) |

Heat resistance | Normal operating temperature -10℃ to +60℃, can withstand up to +80℃ for a short time | Normal operating temperature -35℃ to +80℃, can withstand up to +115℃ for a short time (some high temperature resistant formulas) |

Aging resistance | Ozone and UV resistance, long life | Easy to age (need to add anti-aging agent) |

Transmission accuracy | High (precise tooth shape, low slip) | Medium (elastic deformation may affect synchronization) |

Quietness | Excellent (low vibration, low noise) | Medium (rubber absorbs vibration but may produce friction noise) |

Weight | Light (suitable for high-speed transmission) | Heavy (large inertia, limited high-speed performance) |

3.Differences in application scenarios

Scenario | Polyurethane timing belt | Rubber timing belt |

Applicable industries | Automation equipment, robots, medical treatment, food processing, 3D printing, etc. | Heavy machinery, mining equipment, agricultural machinery, automobiles, printing, labeling, folder gluing machines, high temperature environments, etc. |

Typical working conditions | High precision, high speed, frequent start and stop, clean environment, not easy to generate dust, can be used in food and pharmaceutical industries | High load, high impact, high temperature or dusty environment, severe environmental conditions with large temperature and humidity changes |

Maintenance requirements | Low (lubrication-free, long life) | High (need to check wear regularly) |

4.Cost Comparison

Costs | Polyurethane timing belt | Rubber timing belt |

Initial costs | Higher (high material and process cost) | Lower (low raw material cost) |

Long term costs | Low (long life, less maintenance) | Higher (frequent replacement required) |

Summary of selection suggestions

1.Choose polyurethane timing belt:

*Scenarios that require high precision, wear resistance, and quietness (such as automation, medical equipment);

*Oil-contaminated or clean environments (food processing, laboratories);

*Pursue lightweight and high-speed transmission (robots, 3D printers).

2.Choose rubber timing belt:

*High temperature, heavy load, impact conditions (mining machinery, agricultural equipment);

*Limited budget and low requirements for transmission accuracy;

*Occasions that require vibration absorption and buffering (such as traditional industrial equipment).